When setting up a block for surfacing, depending on the machine used, it may not be possible to use the dial indicator that’s attached to the head of the surfacer (if there even is one). Creating a bar shaped like an L as pictured and mounting a cheap dial indicator to it to “sweep” the deck with the cutter head giving the user the ability to completely level the deck to the cutter head. You’ll have to remove it and use the dial indicator on the machines head to set “touch point” of the tool bit again, though. This cheap fix will also work for large blocks or cylinder heads as well.

Alexander Riggers, C&P Machine, Fort Wayne, IN

DOORSTOP DAMPER

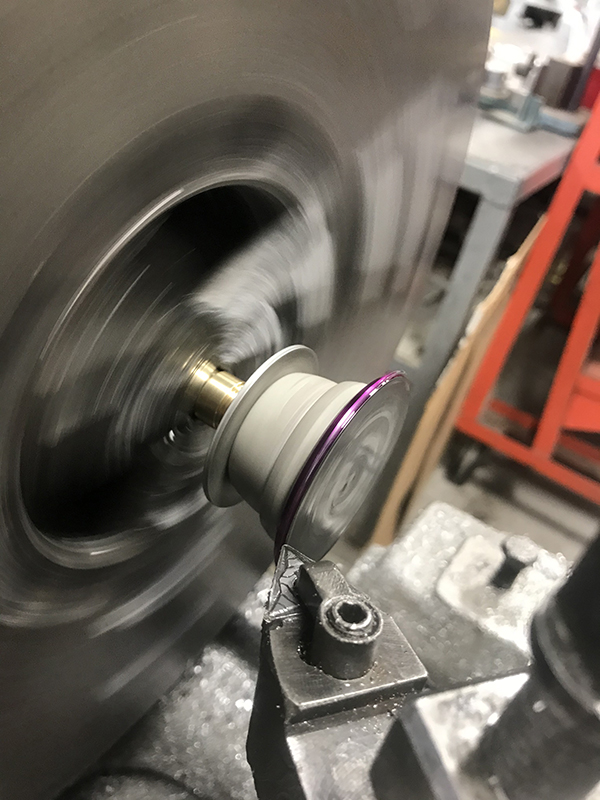

When cutting valve margins down, we use this simple rubber doorstop as a damper to help reduce chatter as we cut the face. We keep various size guides, and washers with it to clamp the valve in the lathe. Using the tail stock, you can press the valve in before tightening to put more pressure on the damper.

Adam Cofer, Don Ott Racing Engines, York Springs, PA

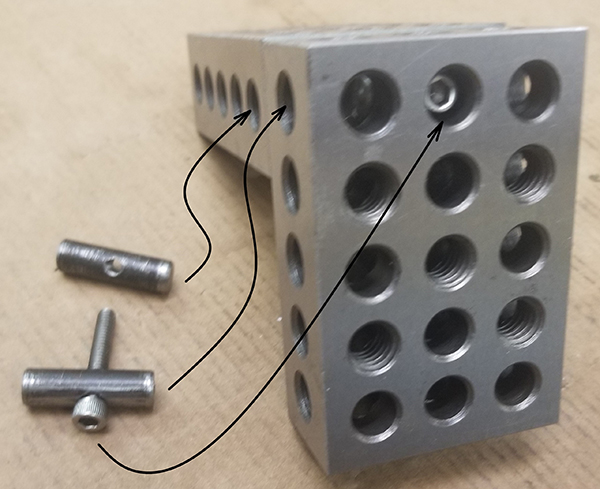

1-2-3 BLOCKING BUILDING

Using 1-2-3 blocks to fixture manifolds or heads on a Bridgeport Mill may sometimes require joining a pair of 1-2-3 blocks. While some 1-2-3 blocks have a few threaded holes, these thread holes don’t always line up where needed. These simple to make “connector pins” slide into the holes of the 1-2-3 blocks, allowing the blocks to be securely fastened together with socket head cap-screws (SHC) in just about any configuration required.

In this example, the 1-2-3 blocks have 10mm holes, so 0.343″ diameter pins were made slightly shorter than 1″. Using pins slightly smaller than the hole diameter allows some movement for positioning adjustments, if needed. One pin is drilled through 0.199″ so a SHC slips through; the other pin is threaded 10-32 to fit the SHC. Longer SHCs can be used to allow several different configurations of the 1-2-3 blocks. An advantage of using these “connector pins” is there are no external fastener bolt heads or nuts to interfere with 1-2-3 block positioning.

Tom Nichols, Automotive Machine & Supply, Inc, Cleburne, TX

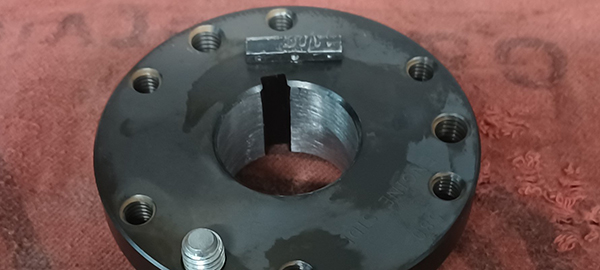

STICKY SITUATION

This trick got me through a job that I didn’t have the correct tooling for. I don’t have a keyway rod hone mandrel in 1.375″ so I cut a piece of 1/4″ key stock in half to keep the shoes and stone on my mandrel from catching and sticking in the keyway slot in this damper hub. I had to dimple the sides of the key stock with a center punch to make it a snug fit in the keyway of the hub. This new “tool” is going in my rod hone box for next time! I also attached a piece of rod that I had laying around as a handle to put on the steady rest bar in the rod hone.

Jake Sampson, Sampson Racing Engines, Inver Grove Heights, MN

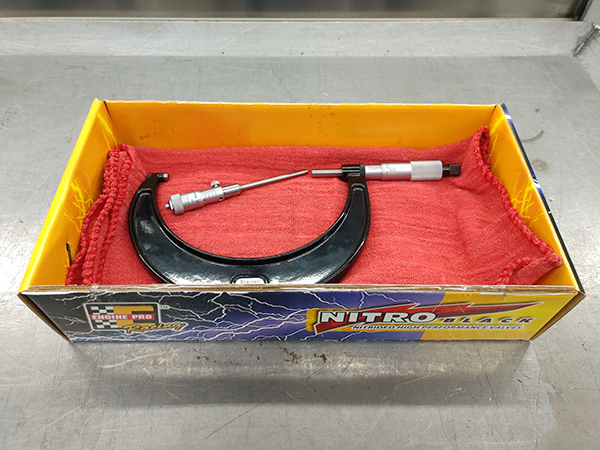

PROTECT YOUR INVESTMENT

Whether you own a shop or work in a shop, take care of your investment in measuring tools. If you’ve ever damaged one you know what I mean. I always set them on shop rags in an old valve box while using them. They stay cleaner and don’t get banged up. Also, they are not influenced by cold workbench tops.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

REFILLS

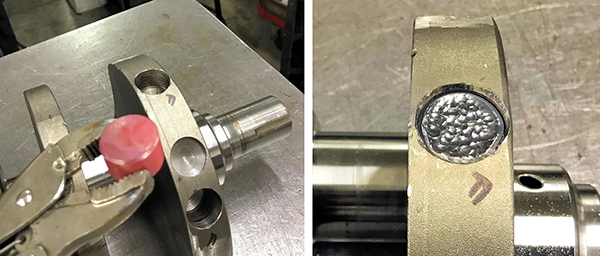

When balancing a crankshaft for heavier parts, often you must add metal in an existing hole. If the hole was drilled with a regular drill bit, versus a spade drill, the hole can be irregular and oversized. It can be time consuming to try to make a slug that fits the irregular hole. I cut an appropriate piece of cold rolled steel of the closest diameter, for the weight to be added. Next, heat it up cherry red. Drop it in the hole and use your air hammer with a blunt round end to work the piece from the center out, to fit the hole snugly. Finally, weld it in place. Always add a little extra for “fine tuning”.

Ron Flood, Cedar Machine, North Branch, MN